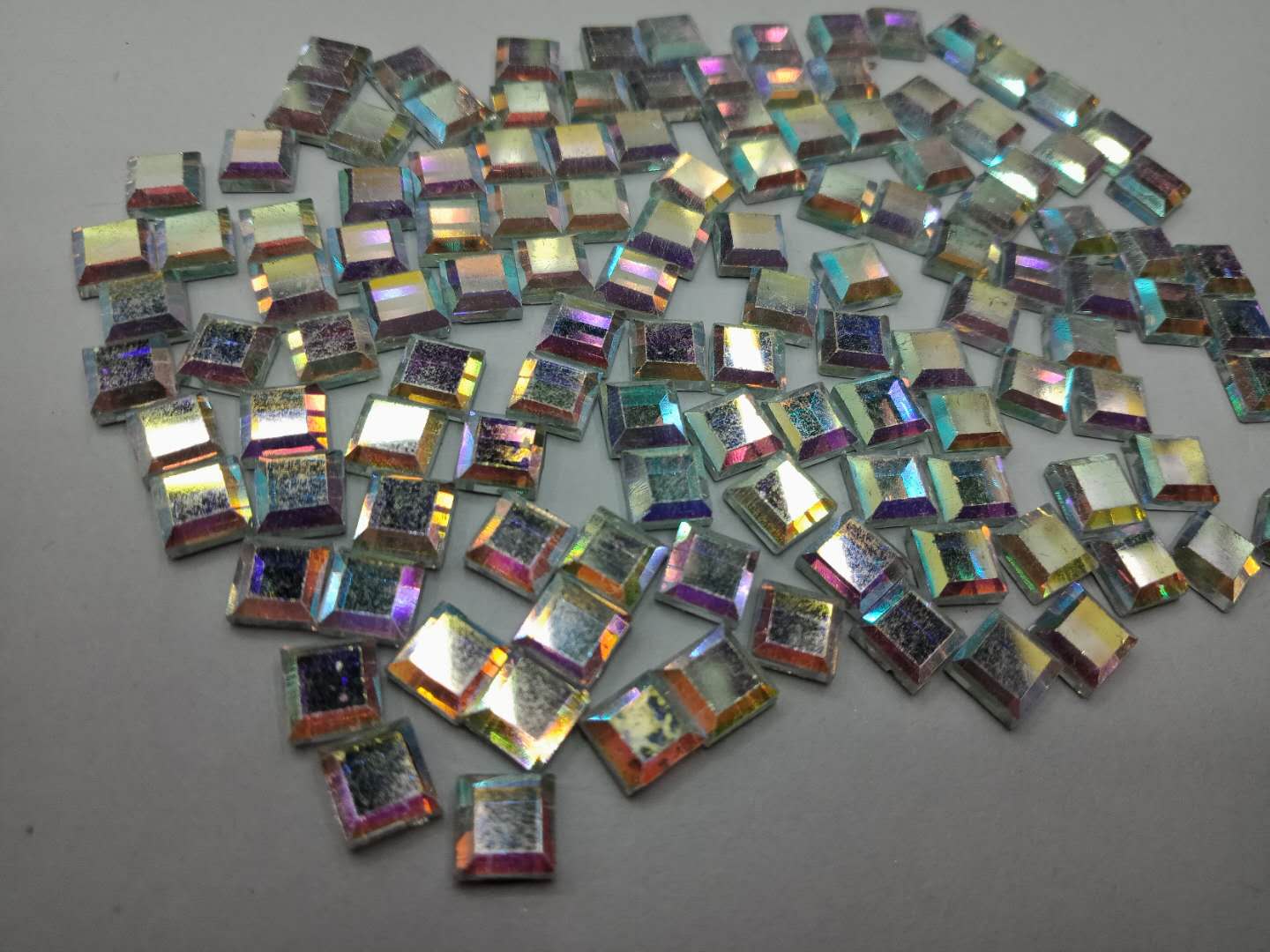

From simple sequins to today's sophisticated Middle East diamonds, the world of DIY accessories is expanding into new frontiers. Especially for the pursuit of personalized handcraft enthusiasts, a high quality material can make your work more brilliant. Today we're going to delve into the charm of the 6x 6 DMC flat bottom drill.

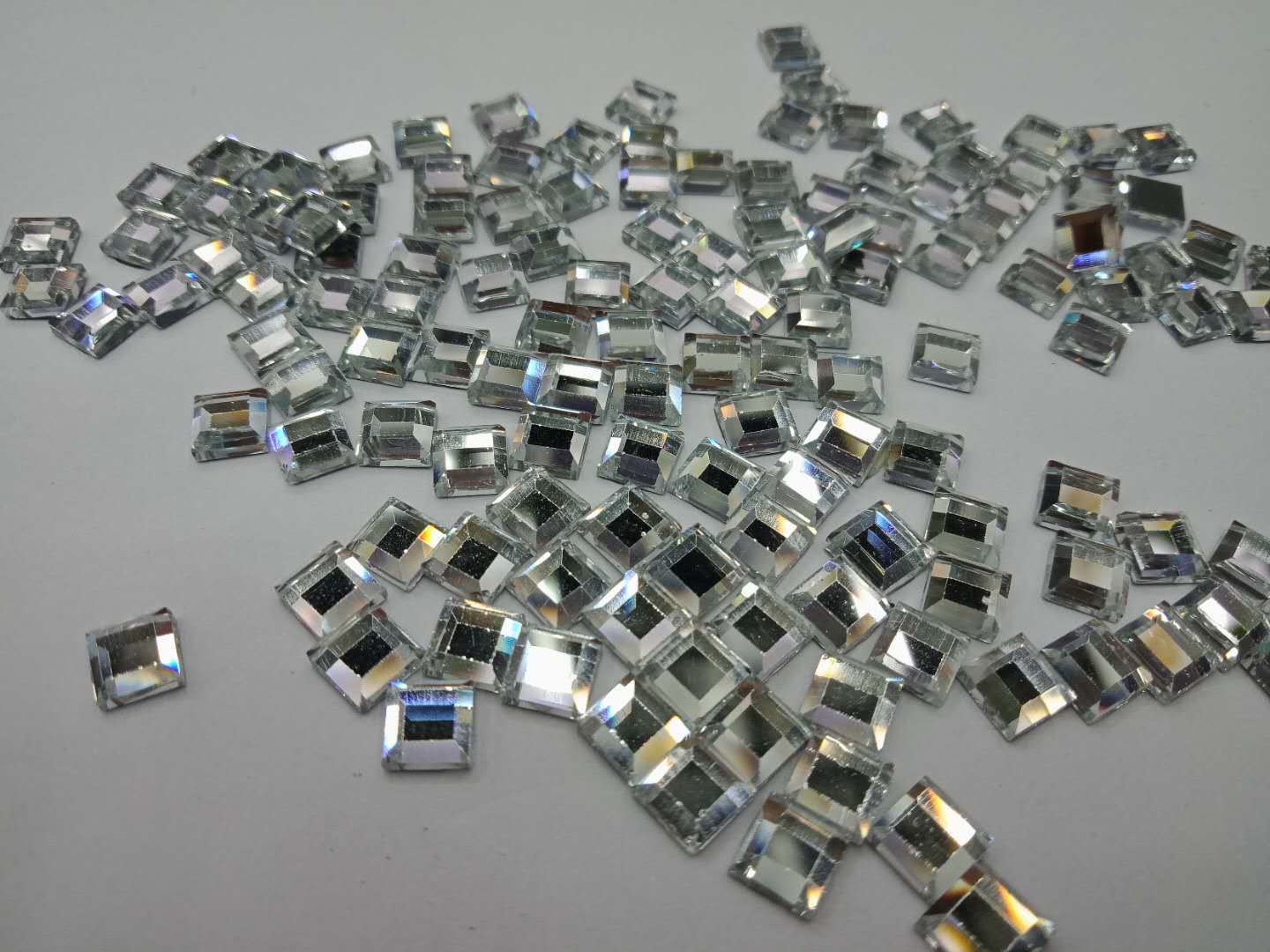

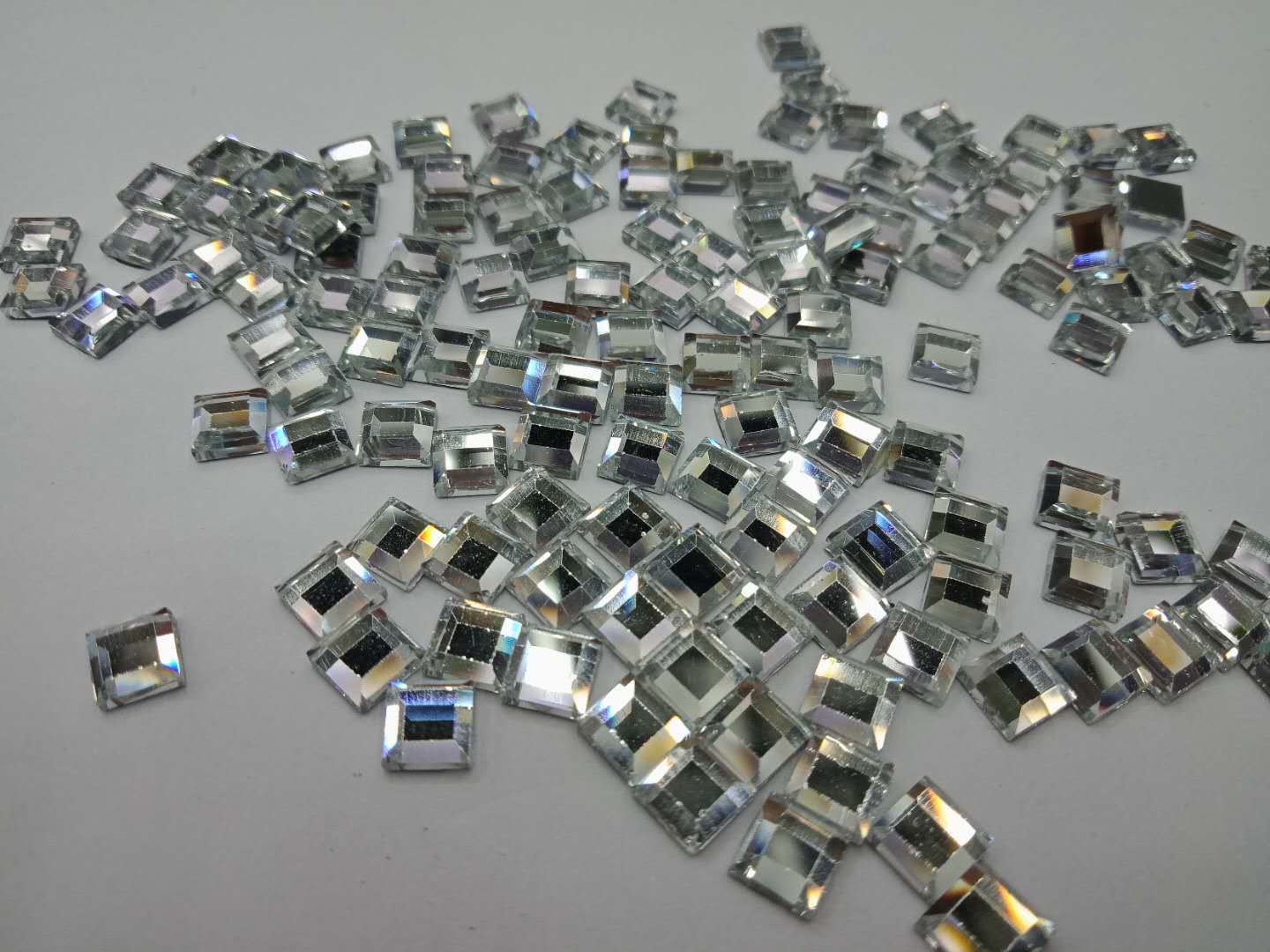

This 6x 6 flat bottom drill adopts advanced manufacturing technology, and its surface is smooth and flat, which can better reflect light and present a dazzling effect. Compared with the traditional water transfer printing technology, this kind of diamond is not only more convenient to install, but also will not fall off due to long-term wearing or cleaning. This makes it one of the preferred materials for all kinds of DIY projects.

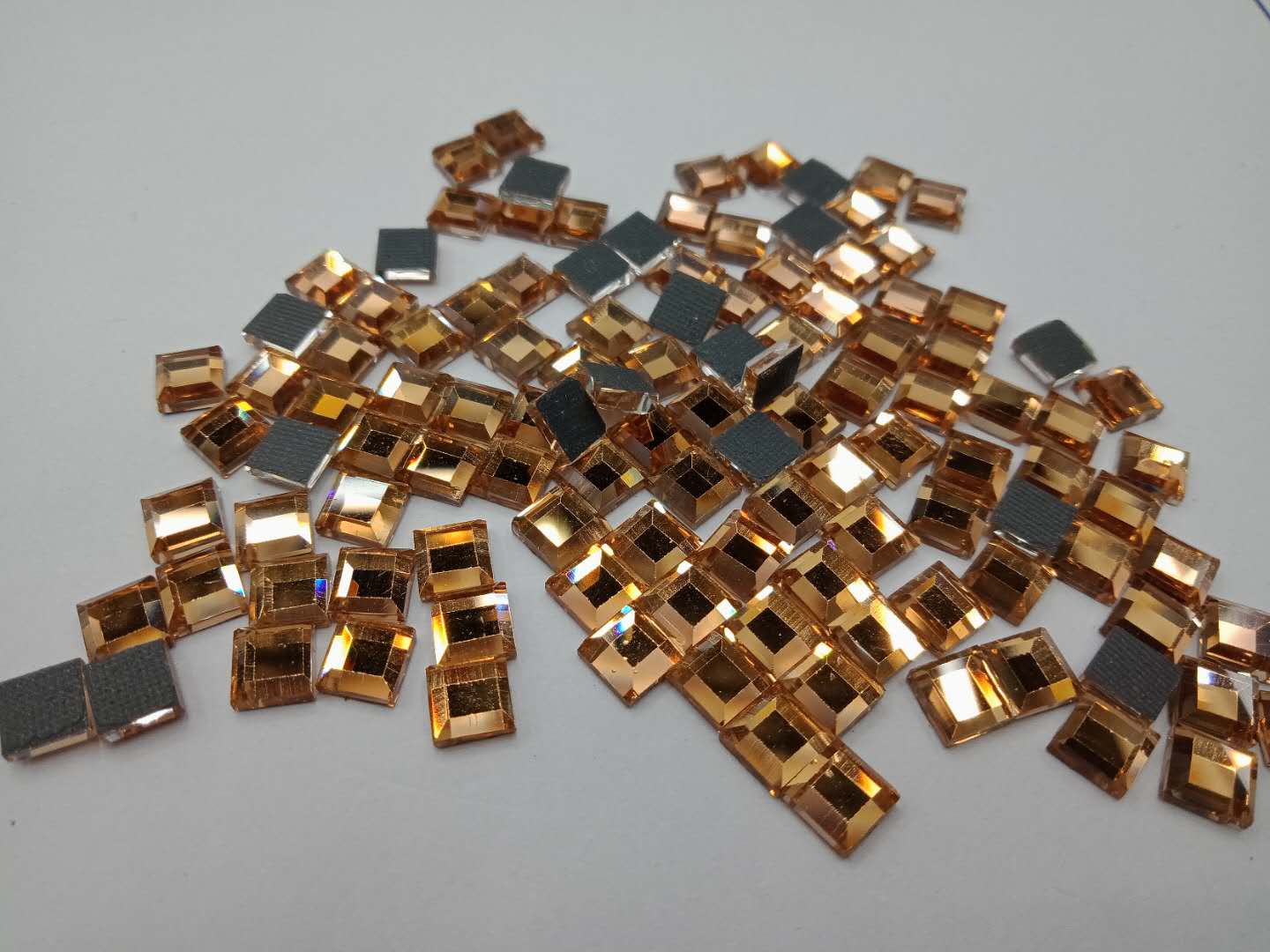

However, some skill is also required in selecting a specific hot drill. The first thing to consider is the color matching problem. Different colors will convey completely different emotional expressions. For example, gold usually symbolizes luxury and nobility, while silver is fresh and simple. In addition, it is necessary to pay attention to the size adaptation. For smaller ornaments, it is recommended to use relatively delicate granular hot drills, while for large pendants, you can choose slightly larger products to highlight the overall styling.

next, let's go into the actual operation and see how to use these small and exquisite but powerful gems to create our own works of art! Take making a classic retro brooch as an example:

- the first step is to prepare basic materials, including metal frames, glue guns and other auxiliary tools;

- The second step is to arrange the position of each diamond according to the pre-planned pattern, and fix it with an appropriate amount of super glue;

- the third step is to wait for it to dry completely and then trim off the excess leftover materials to complete the whole process ~

It is worth mentioning that many well-known brands in the high-end fashion industry have incorporated this concept into the design of wedding dresses. A well-known designer once revealed the reason why she loves such elements: "When the sun shines on the model, the shining part is as charming as the starry sky at night." This shows that they do have irreplaceable status value.

Although this is beautiful, friends in the field for the first time may encounter some challenges. The most common mistake is that excessive force leads to the destruction of the original perfect cutting surface, or fails to accurately grasp the heating temperature, resulting in deformation and other problems. For this, experts give the following suggestions for improvement:

-practice and control the pressure until you master it skillfully

-use special measuring instruments to ensure continuous and stable operation in constant temperature state

Finally, don't forget that daily maintenance is equally important! In order to maintain a good appearance of the finished product after inlaying, please wipe the surface dust and stains regularly and store them in a dry and cool place to avoid erosion and damage the quality in a humid environment.